FREE Shipping over $350

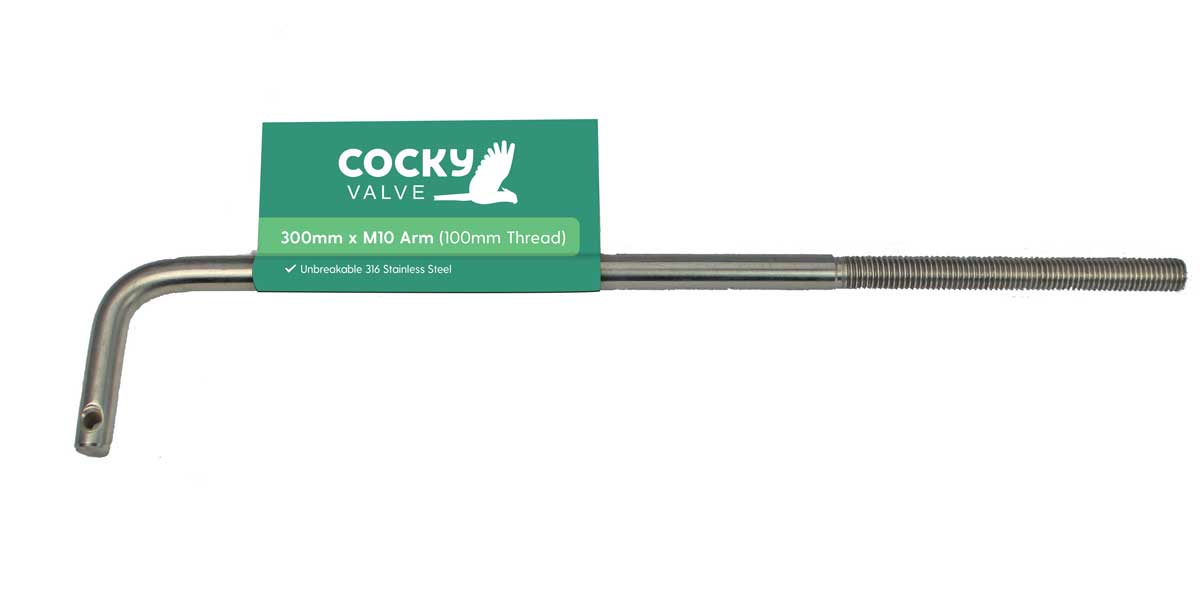

300mmx M10 Float Arm (100mm Thread)

$33.11 (incl. GST)

959 in stock

These are the arms that were developed to allow the customer to cut back the arm when required and still have thread to mount the float.

When fitted to a Ulti Flo Float valve, with an 8” float mounted on the shortest arm, they will still provide a shut off pressure of ≤ 900 Kpa (130 psi.)

All Cocky valve float arms are made from 10mm Ø SS316 rod making them the strongest arms on the market.

- 300mmx M10 Float Arm (100mm Thread)

Flexible fit: The 100 mm thread section allows you to trim the arm’s length to suit your trough or tank setup while ensuring safe float mounting.

High pressure capability: Can handle up to about 900 kPa with an 8″ float, matching performance of standard non-threaded arms.

Robust material: Made with SS316 stainless steel, strong and durable even under harsh environmental or stock pressure conditions.

Safe trimming: The design ensures you still maintain sufficient thread engagement after trimming, protecting against float loosening or failure.

Reliable consistency: Fits with Cocky Valve’s universal float arms, valves, and floats—so replacement or upgrade is straightforward.

1. What does “100 mm thread” mean on this float arm?

It means that the arm has 100 mm of full-length M10 threading so the user can cut back (trim) the arm as needed, and still have enough thread to mount the float securely.

2. What shut-off pressure can this arm achieve with an 8″ float?

When fitted to an Ulti Flo float valve with an 8″ float, it will still be able to shut off at up to about 900 kPa (≈ 130 psi).

3. What material is this float arm made of?

The arm is made from 10 mm diameter SS316 stainless steel rod, offering excellent strength and corrosion resistance.

4. When would someone choose this arm over a standard 300 mm arm?

It’s ideal when the installation requires trimming due to physical constraints (e.g. trough depth or enclosure), but you still need to run an arm close to 300 mm without compromising thread engagement for safety and performance.

These are the arms that were developed to allow the customer to cut back the arm when required and still have thread to mount the float.

When fitted to a Ulti Flo Float valve, with an 8” float mounted on the shortest arm, they will still provide a shut off pressure of ≤ 900 Kpa (130 psi.)

All Cocky valve float arms are made from 10mm Ø SS316 rod making them the strongest arms on the market.

- 300mmx M10 Float Arm (100mm Thread)

Flexible fit: The 100 mm thread section allows you to trim the arm’s length to suit your trough or tank setup while ensuring safe float mounting.

High pressure capability: Can handle up to about 900 kPa with an 8″ float, matching performance of standard non-threaded arms.

Robust material: Made with SS316 stainless steel, strong and durable even under harsh environmental or stock pressure conditions.

Safe trimming: The design ensures you still maintain sufficient thread engagement after trimming, protecting against float loosening or failure.

Reliable consistency: Fits with Cocky Valve’s universal float arms, valves, and floats—so replacement or upgrade is straightforward.

1. What does “100 mm thread” mean on this float arm?

It means that the arm has 100 mm of full-length M10 threading so the user can cut back (trim) the arm as needed, and still have enough thread to mount the float securely.

2. What shut-off pressure can this arm achieve with an 8″ float?

When fitted to an Ulti Flo float valve with an 8″ float, it will still be able to shut off at up to about 900 kPa (≈ 130 psi).

3. What material is this float arm made of?

The arm is made from 10 mm diameter SS316 stainless steel rod, offering excellent strength and corrosion resistance.

4. When would someone choose this arm over a standard 300 mm arm?

It’s ideal when the installation requires trimming due to physical constraints (e.g. trough depth or enclosure), but you still need to run an arm close to 300 mm without compromising thread engagement for safety and performance.