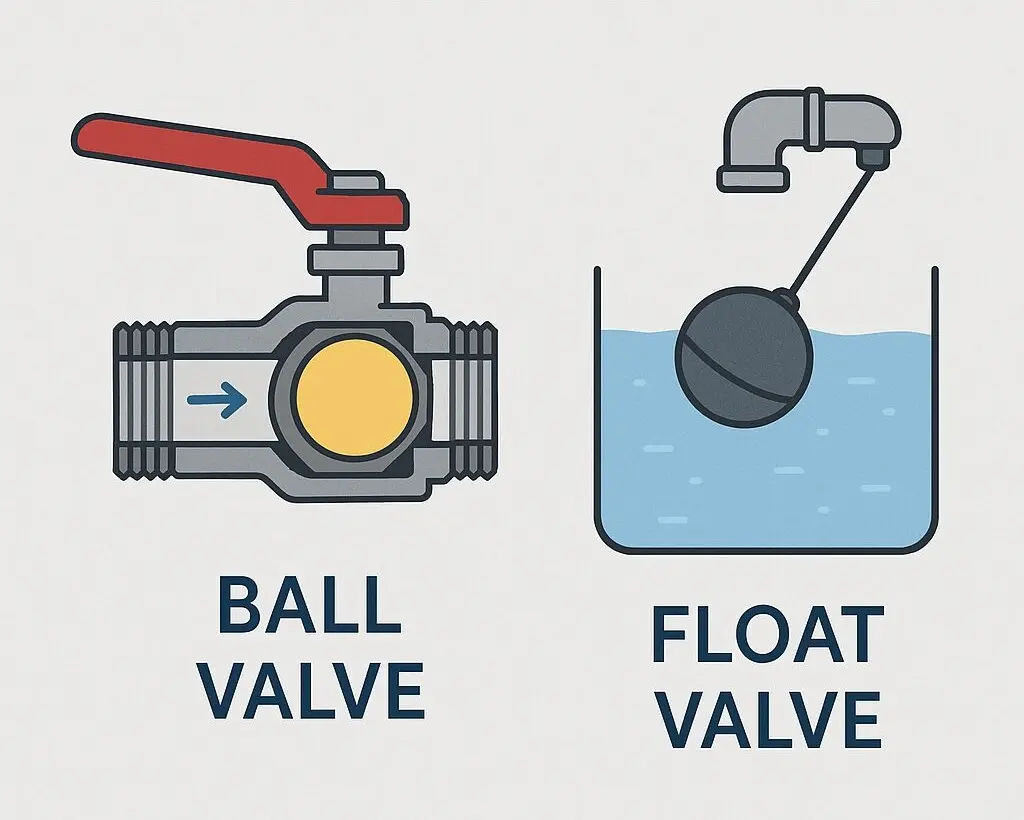

The Differences Between Ball Valves and Float Valves

When it comes to managing fluid control in industrial, commercial, or even residential systems, choosing the right type of valve can make all the difference. Two of the most commonly used valve types are ball valves and float valves. While they both serve important roles in fluid management, their functionality, design, and applications set them apart. Understanding these differences can help you make an informed decision for your system.

Ball Valves & Float Valves: What Are They?

What Are Ball Valves?

Ball valves are versatile devices used to regulate the flow of liquids or gases. They feature a spherical disc (referred to as the “ball”) with a hole drilled through its centre. When the ball is rotated by 90 degrees using a handle or actuator, the hole aligns with the flow path to allow fluid to pass through. Rotating the ball back closes the valve, stopping the flow.

Ball valves are valued for their durability, quick shutoff capabilities, and ability to provide a tight seal even under high pressure. They’re commonly used in industries such as plumbing, oil and gas, and chemical processing.

What Are Float Valves?

Float valves are designed to control the flow of liquids automatically, typically in water storage systems. These valves feature a floating mechanism (usually a hollow ball or similar device) that rises or falls with the liquid level. As the float moves, it either opens or closes the valve to regulate the inflow of water.

Commonly used in tanks, reservoirs, and cisterns, float valves are useful in applications requiring automatic fluid control without manual intervention. They’re often found in agricultural irrigation systems, cooling towers, and water treatment facilities. The simplicity of their design makes them reliable and cost-effective for maintaining consistent fluid levels.

What Valve Is Best for Your Needs?

Choosing between a ball valve and a float valve depends on your specific requirements. If you need precise flow control or a valve that can handle high pressure, a ball valve is likely your best option. Their versatility and durability make them suitable for a range of industrial and commercial applications.

On the other hand, if your main concern is automatic control in a water storage system, a float valve is the best choice. Cocky Valves excel in maintaining consistent fluid levels without the need for monitoring. They are used in cooling towers, tanks, many industrial applications and of course in troughs for the regulation of stock water.

Factors such as operating pressure, temperature, system size, and the type of fluid being managed can all influence your decision. Explore our range of float valves to find the perfect solution for your needs.

Contact Us for Further Assistance

Not sure which valve is right for your system? Contact us today for expert advice and guidance on choosing the perfect float valve for your needs. At Cocky Valve, we’re committed to providing quality products and solutions to meet your fluid control requirements.